About Us

As an MES industrial Asset Management consultant, Paul Juhnke provides a broad, experienced look at Maintenance Management with focused attention on opportunities within the Client’s plant to improve asset reliability, optimize equipment inspections, effectively plan & schedule work, organize and optimize spare parts, direct MRO purchasing, and provide management reports.

Industrial Asset Management consultant

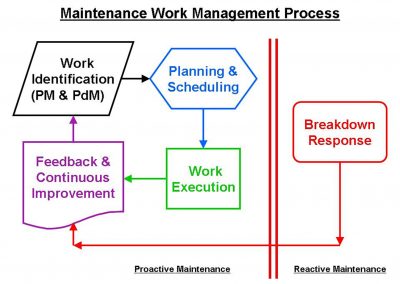

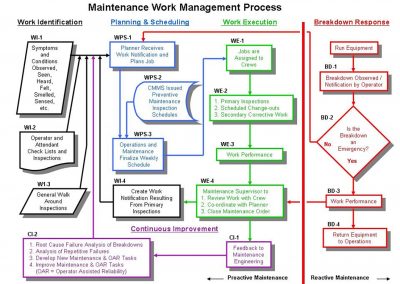

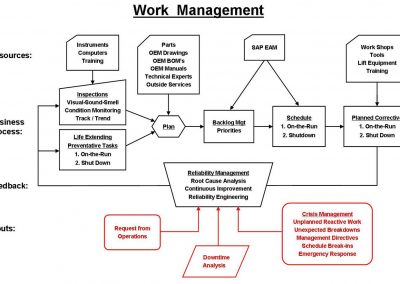

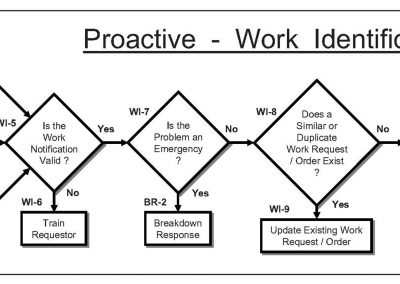

Improvement projects provide craftsmen, supervisors, planners, schedulers, and managers with the technical information, spare parts, tools, plans, directions and schedules they need to function with efficiency, high-productivity, effectiveness, and safety. Clear, simple work management methods including downtime analysis, equipment condition-monitoring inspections, backlog management, planning, spare parts kitting, work scheduling, and shutdown / turnaround management. You can expect quick reliability improvements, increased plant utilization, higher OEE, and better profit margin.

Better plant asset utilization, improved process equipment reliability, increased production throughput, reduced maintenance costs, and improved crew safety are the end result. Paul is well qualified to structure and lead proactive maintenance and change-management efforts.

Our Services

Audits & Gap Analysis, Asset Reliability Assessments

Backlog Management

Backlog, Planning & Scheduling Training

CMMS / EAM Design & Implementation

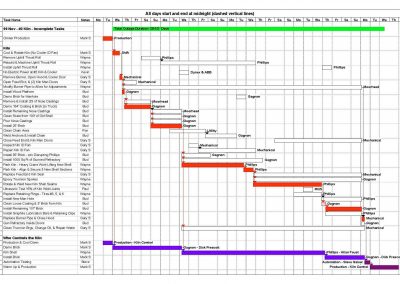

Critical Path Scheduling

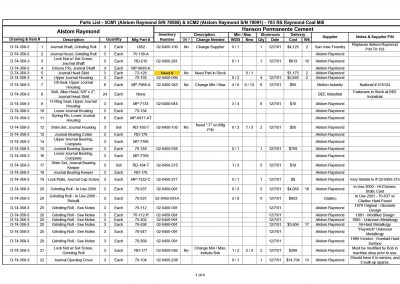

Critical Spare Part Selection

Down Time Analysis

Engineering, Maintenance, Purchasing, Stores & Operations Teamwork Equipment Condition Monitoring Training

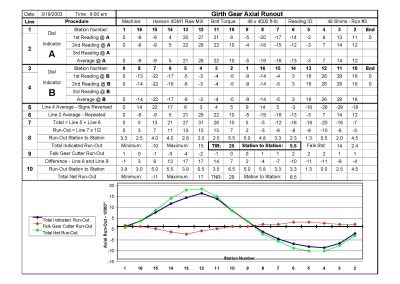

Equipment Inspections

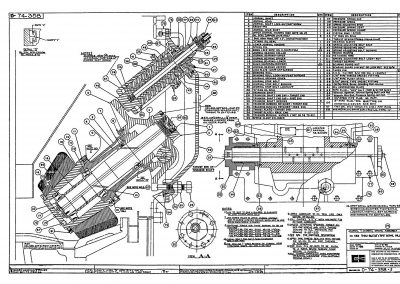

Failure Analysis & Metallurgy

Failure Mode Effect Analysis (FMEA)

Maintenance Management Optimization & Training

Maintenance Work Management Process Documentation

Outage Plans & Management

Parts Kitting Training

Predictive Maintenance

Preventative Maintenance Optimization (PMO)

Reliability Centered Maintenance (RCM)

Reliability Engineering, Analysis & Training

Roles & Responsibilities

Root Cause Failure Analysis (RCFA)

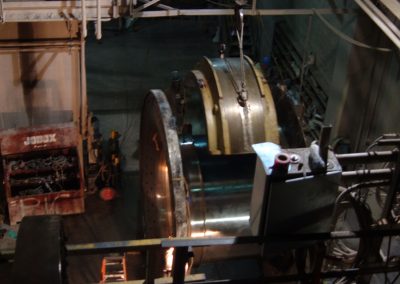

Rotating Equipment Failure Analysis

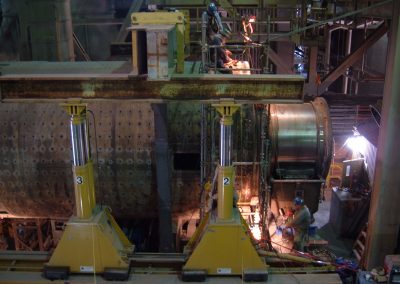

Shutdown & Turnaround Management

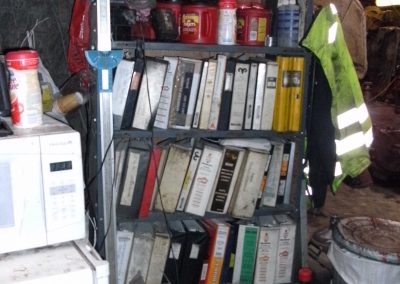

Spare Parts Management (MRO)

Storeroom Right-Sizing

Supervisor Training

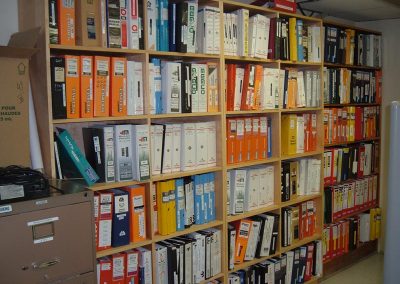

Technical Document Management

Tool Room Management

Uptime & OEE Improvement

Do you have a question about our ASSET MANAGEMENT services?

Our quality of work, with the experience to get it done, is what sets us apart from the rest in our field. We routinely correct problems left behind from previous CMMS / EAM implementations.

Let us know if you have any questions!

Testimonials

Plant Engineer, Portland Cement Plant, California, USA“Paul is a customer focused and dedicated. He delivered very good results and worked well with other consultants and the plant staff. He is mature, knowledgeable and delivers results.”

Get In Touch

Contact Information

Paul Juhnke

Fernley, Nevada 89408-9098

Phone: (641) 420-3996

Email: [email protected]

6 am to 6 pm PST M-F